- Flexo Printing

- Slotting / Die Cutting (Rotary & Flat Bed)

- Folding, Gluing / Stitching

- Bundling

1. Flexo Printing

- Printing can be made with Top or Bottom Printing

- Printing Plate could be rubber or Photopolymer

- Printing unit depend on the needs, from 2 to 6 colors

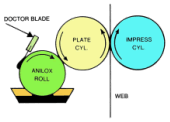

Flexo Printing Process

Conventional Flexo Printing

Modern Flexo Printing

Most of simple job using only 2 solid colors, but for the high quality printing they have used up to 6 colors – though it is rare in this region.

Printing Machine

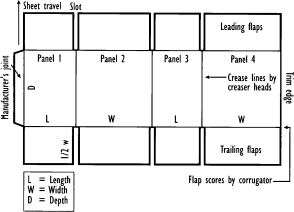

Most of the printing machine always combine with Slotter to make RSC Boxes (Regular Slotted Container).

Printer Slotter with Folder Gluer

- Prefeeder

- Printing Unit

- Creaser/Slotter

- Delivery/Stacker

2. Folder Gluer

- Inline wuth Flexo Printer Slotter

- Offline

- Topfold & Bottomfold

3. Diecutting

Die cut is used for Wrap around boxes, There are 2 kind of die cutting machine :

- Rotary

- Flat Bed

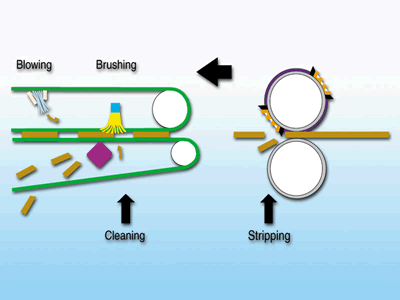

Rotary Die Cutter Operation

More accurate, higher investment but cheaper die.

4. Bundling

Tying the box either from folder gluer / diecutter.

Semi Automatic

Full Automatic Strapping (With Squaring)

Automatic Stacking and Bundling